Unlock the Key Advantages of Using Porcelain Sealers for Superior Longevity and Visual Enhancement

Porcelain sealers are essential for preserving the durability and enhancing the visual appeal of porcelain surfaces. These protective solutions not only amplify the visual allure of your porcelain tiles, countertops, and decorative features but also significantly prolong the lifespan of the materials involved. In Australia, where porcelain is a widely favoured choice for various applications, it is vital for both homeowners and industry professionals to comprehend the different types of sealers available. By understanding the unique characteristics and advantages of these sealers, you can make informed decisions regarding their application and maintenance, ensuring that your porcelain surfaces remain in exceptional condition for years ahead.

Evaluating Impregnating vs. Topical Sealers for Maximum Protection of Your Porcelain Tiles

Across Australia, porcelain surfaces are primarily treated with impregnating (or penetrating) sealers, specially designed to penetrate deeply into the tile, thus providing protection from within while preserving its natural look. These sealers offer a robust barrier against moisture and stains, effectively maintaining the structural integrity of the porcelain. This feature makes them suitable for diverse environments, from bustling indoor settings to exposed outdoor areas, thereby ensuring the longevity and performance of your porcelain installations.

Expert Tips for Efficiently Cleaning and Sealing Your Porcelain Tiles

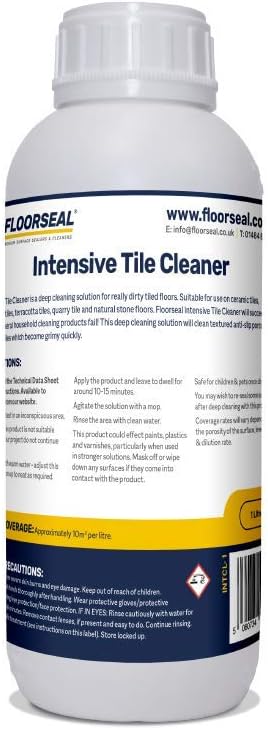

Floorseal

Intensive Tile Cleaner

|

EcoProtect

Porcelain Tile Sealer

|

Stonecare4U

Essential Porcelain Sealer

|

Topical sealers operate by forming a bond with the surface of porcelain tiles, establishing a thin protective layer instead of penetrating the tile itself. Given that porcelain is a high-density, non-porous material, conventional sealers intended for porous surfaces often struggle to adhere effectively. Therefore, topical sealers for porcelain are specifically engineered with adhesion enhancers to ensure a reliable application on the smooth, glass-like surface of the tiles.

-

Topical sealers are commonly solvent-based or petroleum-based rather than water-based, as these formulations bond more effectively to low-porosity surfaces like porcelain. However, the market is witnessing a rise in water-based sealers to accommodate environmental considerations.

-

The adhesion mechanism relies primarily on mechanical bonding (surface film formation) instead of absorption into pores, necessitating specially formulated solutions.

-

To guarantee optimal adhesion, the tile surface must be clean, dry, and devoid of any debris or residues before application, establishing a solid foundation for effective sealing.

-

Once the sealer is applied—typically by spraying or wiping—it requires curing; failing to allow adequate curing can result in peeling or ineffective bonding.

-

Regular maintenance is crucial, as the topical layer may wear down over time, necessitating reapplication to sustain its protective qualities.

If a topical sealer is not specifically designed for porcelain, or if the application instructions are not followed (such as inadequate cleaning or curing), the sealer may fail to bond correctly, leading to premature peeling. It is always advisable to consult the manufacturer’s guidelines to achieve the best possible outcomes.

The Indispensable Role of Sealers in Protecting Porcelain Surfaces

The application of sealers on porcelain surfaces goes beyond mere visual enhancement; it serves as a critical step in ensuring the longevity and structural integrity of the material. While many manufacturers claim that porcelain is non-porous, it is essential to recognise that tiles can display micro-porosities due to irregular or subpar manufacturing processes—defects that may go unnoticed by the manufacturer. These hidden vulnerabilities can render the tiles susceptible to staining, moisture infiltration, and long-term deterioration.

This is precisely why employing an impregnating (penetrating) sealer is regarded as best practice. Such sealers infiltrate the tile, establishing an invisible barrier within the surface to obstruct contaminants and moisture while preserving the finish. Considering Australia’s varied climate, particularly in older homes, this protective measure is vital for preventing discolouration and sustaining both the aesthetics and functionality of the tiles. Furthermore, penetrating sealers subtly enhance the natural beauty of the tiles, making them ideal for decorative settings where appearance is paramount. Selecting the appropriate sealer not only protects your tiles but also ensures long-lasting performance, aligning with the expectations of discerning homeowners.

How to Determine When Your Sealer Needs Reapplication or Stripping

Identifying when a porcelain sealer requires stripping or reapplication is crucial for preserving the quality of your surfaces. Observable indicators such as discolouration or dullness suggest that the sealer has lost its effectiveness. Moreover, if water fails to bead on the surface, this serves as a clear signal that the protective layer has been compromised and demands immediate attention.

Given that sealers are typically invisible to the naked eye, detecting wear and degradation can be challenging without appropriate testing. Tactile changes, like a rough or sticky texture, may imply that the sealer has begun to deteriorate, although these signs are not always evident. Homeowners should routinely evaluate their sealed porcelain by performing a straightforward water droplet test: place a few drops onto the tile surface. If the water spreads and absorbs, the sealer has worn away. Conversely, if the droplets bead up, the protective layer remains intact and functioning optimally.

Emphasising Safety During the Stripping of Porcelain Sealers

When engaging in the process of stripping porcelain sealers, prioritising safety is of utmost importance. The procedure often involves the use of chemical products that require careful handling and the implementation of appropriate protective measures to ensure a safe working environment.

Essential Protective Gear When Handling Stripping Agents

Utilising suitable protective equipment is imperative when working with sealers and stripping agents. At a minimum, individuals should wear gloves to protect their hands from harsh chemicals that could cause skin irritation or allergic reactions. Additionally, safety goggles are essential to safeguard the eyes from splashes and fumes, which can lead to serious injuries.

A well-fitted mask or respirator is also highly recommended to prevent inhalation of harmful vapours. In Australia, where regulations surrounding chemical handling are stringent, the proper use of protective gear is not only vital for personal safety but also for adherence to health and safety standards. Always remember that prevention is preferable to cure; investing in high-quality protective gear can shield you from numerous potential hazards.

Ensuring Adequate Ventilation During the Stripping Process

Maintaining proper ventilation is crucial when using chemical strippers, especially indoors. The fumes released from these products can pose significant health risks, potentially leading to respiratory issues or chemical exposure. To create a safe working environment, open windows and doors to encourage a cross-breeze, ensuring that fresh air circulates effectively. In smaller spaces, using fans to direct vapours outside can greatly enhance safety.

If feasible, conduct stripping activities outdoors or in well-ventilated areas such as garages or sheds. Although the unpredictable Australian weather may not always permit this, careful planning around ventilation can significantly contribute to a safer workspace. Always remain vigilant regarding air quality; if fumes become overwhelming, take a break and step outside until it is safe to return.

Responsible Procedures for Managing and Disposing of Chemicals

When working with chemical strippers, it is crucial to adhere to manufacturer guidelines to effectively mitigate risks. Always read labels and instructions meticulously, as they provide essential information regarding safe usage, including dilution ratios and specific application techniques. In Australia, strict regulations govern the disposal of chemical waste, and compliance with these guidelines is vital to safeguard both human health and the environment.

Moreover, all chemical products should be stored securely, out of reach of children and pets. It is essential to understand the appropriate disposal methods for unused products or residues; many local councils in Australia offer hazardous waste collection services to ensure safe disposal. By following these guidelines, you contribute to a safer environment while protecting your health and that of those around you.

Making Informed Choices When Selecting Chemical Strippers

Chemical strippers are often the preferred solution for removing porcelain sealers, but selecting and using them judiciously is vital to avoid unintended damage. Understanding the various types available—and their specific strengths and weaknesses—can facilitate a smoother and safer stripping process.

Finding the Right Chemical Stripper for Your Requirements

In Australia, chemical strippers come in a variety of formulations:

- Solvent-based strippers are well-known for their rapid action and efficiency in removing tough residues, but they emit strong fumes and necessitate strict safety precautions. They are best suited for well-ventilated environments and professional use.

- Bio-based strippers, formulated from natural ingredients, are gentler on both users and the environment. While they are safer, they generally require longer dwell times to achieve the desired results.

- Water-based strippers present a balanced option—low in toxicity and suitable for indoor use, where air quality and user safety are paramount.

Before using any product, always ensure that it is compatible with porcelain, as incorrect formulations can compromise the tile surface and lead to costly repairs.

Key Tools Required for Stripping Porcelain Sealers

For most stripping projects, it is unnecessary to completely eliminate impregnating sealer residues, as these typically reside deep within the tile pores. Instead, the focus should be on thorough cleaning. Employ a high-quality alkaline cleaner to remove surface contaminants like dirt, grease, and oil. This step ensures proper adhesion for any new sealer that will be applied to the tiles and grout, while maintaining the protective layer already embedded within the material.

Best Practices for Effectively Applying Chemical Strippers

Applying chemical strippers requires a careful and systematic approach to ensure both safety and effectiveness throughout the process. Start by preparing the work area: remove any furniture or items that could sustain damage. Use a paintbrush or roller to evenly apply the stripper across the surface, ensuring a thick, uniform layer is created to maximise effectiveness.

Allow the chemical to sit for the duration specified on the product label. This waiting period is critical, as it enables the stripper to penetrate the sealer and dissolve it effectively. After the designated time has elapsed, gently use a scraper to remove the dissolved sealer. Exercise caution to avoid scratching the porcelain surface; a plastic scraper is often preferable for this purpose.

Always refer to the specific guidelines for the chemical being used, as application techniques may differ. Knowing the safest way to strip porcelain sealers not only ensures the successful completion of the task but also protects the integrity of your porcelain surfaces.

Neutralising and Cleaning Up After the Stripping Procedure

After completing the stripping process, it is essential to neutralise any residues left behind to prepare the surface for re-sealing. Many chemical strippers necessitate neutralisation with water, while others may require specific neutralising agents. Always follow the product instructions carefully to achieve optimal results.

Once neutralised, clean the area thoroughly to eliminate all traces of the stripper. This step is crucial, as any remaining chemicals can interfere with the application of new sealers. Use clean water and a mop or rag to wipe down the surface, ensuring it is free from dirt and chemical remnants. Proper cleanup is vital for ensuring that the newly sealed surface adheres effectively and performs at its best.

Leveraging Mechanical Agitation Techniques to Improve the Stripping Process

While chemical strippers are key for removing porcelain sealers, mechanical agitation serves as a supplementary technique—particularly beneficial for accelerating the action of the chemical without damaging the tile surface itself. Given that porcelain is dense and often glazed, abrasive methods such as sandpaper, scrapers, or steel wool are not recommended, as they can inflict irreversible harm to the surface.

Implementing Safe and Effective Mechanical Agitation Techniques

Mechanical agitation should focus on enhancing the performance of chemical strippers, especially in textured areas and grout lines. The most effective methods include:

- Stiff bristle brushes for manual scrubbing of grout and textured regions, enabling thorough cleaning without harming the tile.

- Red pads on a rotary floor machine for gentle agitation across larger areas, boosting the efficacy of the stripping solution.

- Detail brushes or white pads for intricate edge work, ensuring no risk is posed to the tile finish.

These tools assist in breaking down sealer residues and embedded contaminants without compromising the tile. Always allow the chemical stripper to dwell for the recommended duration before applying mechanical agitation. Rushing through the process or overworking the surface may reduce effectiveness and increase the likelihood of errors.

Safety Precautions When Using Mechanical Methods

Safety must remain a top priority when employing mechanical methods. Always wear eye protection to guard against flying debris and dust. Gloves are also advisable to protect your hands from cuts or abrasions. Maintaining a clean workspace is essential; ensure that any dust or residue is promptly cleared away to prevent accidents.

Consider using a dust mask to prevent inhalation of fine particles, especially when sanding or working with materials that generate dust. Additionally, ensure that the porcelain surface is securely attached to prevent any movement during the stripping process. Adhering to these safety measures will not only protect your well-being but also enhance the overall effectiveness of your work.

Proper Maintenance and Storage of Your Tools After Use

Once the stripping job is completed, maintaining your tools is essential to ensure their longevity and continued functionality. After each use, thoroughly clean all abrasive tools to remove any sealant residue that may have accumulated during the process. Store them in a dry environment to prevent rust or degradation, particularly for metal scrapers and brushes.

Investing in high-quality tools can significantly impact the success of future projects. Regular inspections for wear and tear will help identify when it is time to replace your tools. Keeping your equipment in optimal condition guarantees that you achieve the best results every time you undertake a project, including understanding the safest way to strip porcelain sealers.

Exploring Eco-Friendly Solutions for Stripping Porcelain Sealers

As awareness of environmental issues rises, many individuals in Australia are actively seeking eco-friendly alternatives for stripping porcelain sealers. These options can be less harmful while still providing effective results.

Utilising Natural Strippers for Sustainable Practices

Natural strippers often use plant-based ingredients to break down sealers without relying on the harsh chemicals commonly associated with traditional strippers. In Australia, products formulated from citrus or soy are popular options. These alternatives are generally safer for both users and the environment, minimising harmful fumes and residues.

Many natural strippers can also be applied indoors without the same concerns regarding toxic exposure as their chemical counterparts. However, it is important to acknowledge that while they are less harmful, they may require extended application times to achieve the same level of effectiveness as stronger chemical strippers.

Application Techniques for Natural Strippers

Applying natural strippers follows a similar procedure to traditional methods. Use a brush or roller to evenly coat the surface, allowing sufficient time for the product to penetrate and work effectively. It’s imperative to adhere to the manufacturer’s instructions regarding application times, as different products can vary significantly in their efficacy.

Once the natural stripper has fulfilled its function, use a soft cloth or scraper to remove the sealer, exercising care not to damage the porcelain surface. Rinse thoroughly with water to ensure that all stripper residues are eliminated before allowing the surface to dry completely.

Effectiveness and Limitations of Eco-Friendly Strippers

While eco-friendly alternatives offer a safer option, they do come with certain limitations compared to traditional chemical strippers. For heavy-duty stripping tasks, natural products may not deliver the same speed or efficacy, necessitating additional effort and time.

However, for routine maintenance or lighter sealing applications, eco-friendly strippers can be more than adequate. They are especially valuable for environmentally conscious individuals seeking to minimise exposure to harsh chemicals. Understanding the safest way to strip porcelain sealers while prioritising eco-friendly options aligns perfectly with a sustainable lifestyle.

Determining When to Seek Professional Help for Stripping Services

In certain scenarios, enlisting professional assistance for stripping porcelain sealers is the most sensible choice. Recognising when to engage experts can save time and prevent potential damage to your surfaces.

Identifying Situations That Require Professional Help

There are specific circumstances that warrant hiring professional services for stripping porcelain sealers. If the porcelain surfaces are extensive or intricately designed, attempting the task without adequate experience can lead to costly errors. Additionally, if the previous sealing job involved complex layers or particularly resilient sealers, a professional’s expertise will ensure thorough and safe removal.

Furthermore, if you are unfamiliar with handling chemicals or mechanical tools, the risks associated with improper use of chemical strippers or abrasives can result in significant damage or health complications. In such cases, seeking professional assistance alleviates concerns and guarantees a satisfactory outcome for your project.

Tips for Choosing a Reliable Service Provider

When searching for a professional service for stripping porcelain sealers in Australia, prioritise reputable companies with proven track records. Online reviews, testimonials, and recommendations from friends or family can provide valuable insights. Ensure that the provider is licensed and insured, protecting you from potential liabilities during the stripping process.

It’s also wise to inquire about the methods and products they utilise to ensure they align with your preferences, especially if you have an interest in eco-friendly options. A reputable service provider will be transparent about their processes and willing to address any questions you may have.

What to Expect When Hiring Professionals for Stripping

Engaging professionals for stripping porcelain sealers typically involves a systematic approach. Initially, they will assess the condition of the porcelain and the type of sealer that has been applied. This evaluation enables them to determine the most effective stripping method.

Once the assessment is complete, the professionals will prepare the workspace, shielding surrounding surfaces from dust and damage. They will then proceed with the stripping process using their chosen method, whether chemical or mechanical, ensuring safety and efficiency throughout the operation. After completing the stripping, they will clean up the area and may provide recommendations for re-sealing or ongoing maintenance.

Understanding the Financial Aspects of Hiring Professionals

Gaining insight into the costs associated with professional porcelain sealer stripping services in Australia is vital for effective budgeting. Prices can vary significantly based on factors such as the size of the area, the type of sealer being removed, and the methods employed. On average, homeowners can expect to pay between AUD 100 and AUD 300 for professional stripping services, depending on these variables.

While this may seem costly initially, hiring professionals can ultimately save money by preventing damage that could arise from DIY attempts gone awry. It is advisable to obtain quotes from multiple service providers to ensure you receive the best value for your investment.

Ensuring Compliance with Legal and Safety Standards When Hiring Professionals

It is crucial to verify that the selected professional service complies with Australian regulations and safety standards when stripping porcelain sealers. Reputable companies will adhere to all relevant health and safety guidelines, creating a safe working environment for both their employees and clients.

Don’t hesitate to inquire about their safety protocols and environmental practices. A responsible service provider will prioritise safety and sustainability, aligning with your values. This not only protects you during the stripping process but also contributes positively to the community and the environment.

Essential Care for Your Porcelain Surfaces Following Stripping

After finishing the stripping process, proper care of the porcelain surface is vital to preserving its beauty and longevity. Following the correct procedures ensures that the freshly stripped surface is primed for re-sealing or additional treatments.

Thoroughly Cleaning the Surface After Stripping

Cleaning the surface thoroughly post-stripping is essential for removing any lingering residues and ensuring that the new sealant adheres properly. Begin by rinsing the area with clean water to wash away any remaining chemicals or dust. For stubborn residues, a soft cloth or non-abrasive sponge may be necessary to avoid scratching the porcelain.

Once cleaned, allow the surface to dry completely before applying a new sealer. This ensures that no moisture is trapped beneath the sealant, which could lead to future issues such as mould growth or peeling. Regular maintenance and cleaning of stripped surfaces will help them retain their optimal appearance and functionality for years to come.

Addressing Commonly Asked Questions About Stripping Porcelain Sealers

What is the safest method for stripping porcelain sealers?

The safest approach involves using protective gear, ensuring proper ventilation, and selecting suitable stripping methods, whether chemical or mechanical. Always follow the manufacturer’s instructions to ensure safety and effectiveness.

How often should I strip and reapply porcelain sealers?

The frequency of stripping and reapplying porcelain sealers generally depends on the level of wear and tear. Typically, it is recommended to inspect surfaces every 1-3 years; however, regular checks for signs of wear are advisable.

Is it feasible to strip sealers myself, or should I hire a professional?

This largely depends on your experience and the size of the area in question. DIY methods may be suitable for small jobs, but hiring professionals is advisable for larger or more complex projects.

What environmental impacts are associated with chemical strippers?

Chemical strippers can release harmful fumes and pollutants into the environment. Eco-friendly alternatives are available that minimise environmental impact and reduce exposure risks.

How can I determine if my porcelain sealer needs stripping?

Indicators include discolouration, dullness, or water failing to bead on the surface. These signs suggest that the effectiveness of the sealer has diminished significantly.

Are eco-friendly strippers effective for stripping sealers?

Yes, eco-friendly strippers can be effective, especially for lighter applications. However, they may require longer than traditional chemical strippers for more heavy-duty tasks.

What protective gear is necessary when stripping sealers?

Essential protective gear includes gloves, safety goggles, and a mask to safeguard against inhalation of fumes and exposure to harsh chemicals.

How should I dispose of chemical strippers properly?

Follow local regulations regarding the disposal of hazardous waste. Many councils in Australia offer collection services for safe disposal of chemical products.

What maintenance is required after stripping porcelain surfaces?

Post-stripping maintenance involves thoroughly cleaning the surface and ensuring it is properly dried before reapplying any new sealers.

Can mechanical methods cause damage to porcelain surfaces?

Yes, improper use of mechanical methods can indeed damage porcelain. Always employ appropriate tools and techniques to minimise the risk of scratches or chips.

The Article Porcelain Tile Nightmare: How to Strip Sealers Without Ruining Your Floor first found on https://www.abbeyfloorcare.co.uk

The Article Stripping Sealers from Porcelain Tile Without Damage appeared first on https://fabritec.org

The Article Stripping Sealers from Porcelain Tile Safely and Effectively Was Found On https://limitsofstrategy.com

References:

https://limitsofstrategy.com/stripping-sealers-from-porcelain-tile-safely-and-effectively-2/